Four Key Points to Remember About Custom Overlays for LED Illumination

The brightness, quality, and consistency of visible light displayed via any screen or surface is dependent on a number of variables. These include power and efficiency of the entire LED system, design of the lightguide use, as well as the design of the overlay itself.

Here are four key points to remember about custom overlay design when the end product will be coupled with an LED illuminated backlight that will offer a substantial impact on your final product.

Surface Must Be Highly Reflective

The surface of the overlay that is in contact with the lightguide must be as reflective as possible in order to allow for maximum efficiency. Ideally, the bottom surface is reflective and white. A rough surface, or one that is dark or black in color, will actually absorb light, reducing efficiency.

Surface Cannot Be in Wetted Contact

The overlay surface cannot be in wetted contact with the lightguide in the illumination area, which is the area where light is actually passing through. This means that adhesives or bonding agents cannot be applied where light is designed to travel. Otherwise, total internal reflection(TIR) of the light is interrupted, uneven, and inefficient.

Higher Transmission Rate Equals More Light

When designing custom overlays for illumination, another key point to remember is that the higher the transmission rate of the overlay, the more light that ends up traveling through it. The reason this is important is that clear, or nearly clear, overlays can utilize lightguide systems with much lower power and still produce the same emission as a diffused surface. In instances when the illumination area cannot be left clear, then translucent inks should be allowed.

Many Processes Can Produce Custom LED Overlays

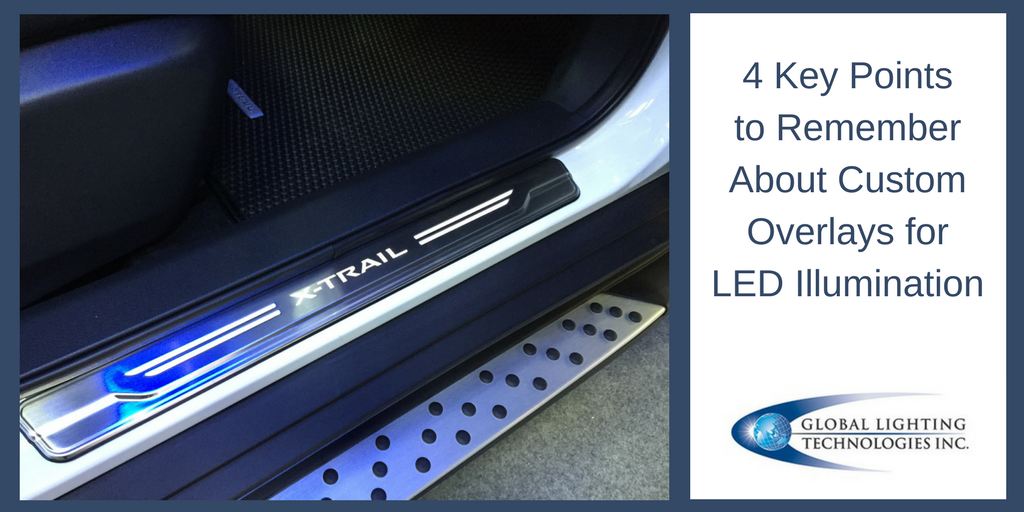

There are many different options for how to create and manufacture a custom overlay for illumination. Any path that results in the transmission of light can be used, which means screen printing with transmissive inks, laser etching to remove ink from surfaces and therefore create new transmissive areas, micro perforations of materials such as aluminum or steel to allow transmission of light, or even die cutting of non-transmissive materials to create transmissive cutouts. The right way forward for your project will depend on the specifics of the project in question, but it’s important to remember that there are numerous potential options and solutions.

Global Lighting Technologies offers a wide array of backlighting services, products and technologies. We pride ourselves on delivering a high-end custom lighting solution for every client, and the best results are always achieved through proper planning and coordination at every step of the process. For more information on our work with custom LED overlays or any other products, contact us here or call 866-922-4584 to speak with a representative.