I’m continually impressed by research and development that leads to innovations like compact smart devices, sleek automotive interfaces, and touch-responsive appliances. As a company at the forefront of research and development, my team has paid close attention to rising user expectations for dynamic visual feedback and aesthetic integration.

Meeting this demand requires unique approaches to light management. At GLT, we’ve taken a bold step in redefining how a single light guide can control light output with precision. Our newest R&D initiative—what we call segmented illumination—is a major development I’m excited to talk about.

The Opportunity

The inspiration for segmented illumination originated from a customer seeking a more elegant solution for indicating brightness levels for their wall-mounted device. Traditional light guide approaches required multiple components or compromised visual clarity. Our engineering team saw a broader potential: what if we could selectively illuminate zones within a single light guide without adding layers or complexity? I brought the question to my team and we were all up for the challenge!

The Solution

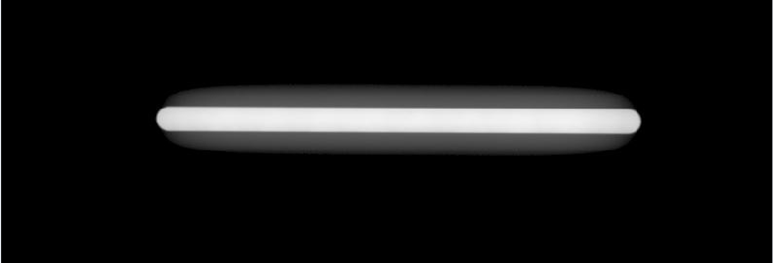

Months of research and development, iterations, and testing resulted in a new way to control light distribution. Our team engineered grooves within a single molded light guide to create optical boundaries between illumination zones. These structures confine light within specific segments, enabling controlled illumination of individual areas. When multiple segments are activated simultaneously, the entire light guide appears uniformly lit: a seamless blend with no visible demarcations. This dual-mode capability offers both precise zone indication and full illumination.

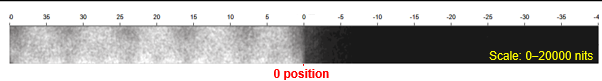

At left, light guide grooves that enable segmentation. At right, multiple segments activated next to un-activated sections.

Developing this groove structure required a delicate balance. The design had to minimize light bleed between zones while preserving overall uniformity. Using advanced optical simulation software, we fine-tuned groove geometries and placements. Due to the nuanced nature of the groove design, traditional prototyping methods proved insufficient. We invested directly in production-grade molded prototypes to ensure accurate performance validation.

Challenges arose in manufacturing consistency and simulation alignment, but we overcame these by iterating rapidly between simulation and production feedback. The final design successfully delivered high contrast ratios and minimal light leakage: a visual clarity that surpassed traditional selective illumination methods.

Research & Development Results

Initial test results showcased the potential of segmented illumination. In brightness control applications, for example, users can visually gauge output levels via five illuminated segments, each distinctly visible yet part of a unified aesthetic when fully activated. This segmentation clarity allows intuitive user interactions while preserving a clean, high-end design.

Figure A demonstrates light guide segmentation

Figure B demonstrates the illumination of the entire light guide

Compared to multi-piece solutions that require complex assemblies or additional housing materials, our single light guide approach reduces costs, enhances reliability, and expands design flexibility. The method is particularly advantageous for products requiring dynamic feedback, such as capacitive touch interfaces, ambient condition displays, or gradient indicators.

While the original project did not reach market due to external business changes, the technology proved production-ready. The underlying principle of segmented illumination within a single molded light guide continues to spark interest. We see strong future potential in automotive lighting clusters, medical diagnostic tools, and industrial control panels! Further research and development are required per application, but we’ve laid a strong foundation.

Research & Development are Part of Our DNA

The research and development that contributed to this segmented illumination innovation underscores our commitment to furthering industry innovations. By exploring how a single molded light guide can deliver controlled, seamless, and responsive lighting, we open new possibilities for OEMs seeking elegant and functional light-based communication.

As this approach evolves, it promises to support next-generation devices where space is tight, feedback needs are high, and aesthetics are paramount. I invite OEMs, engineers, and designers to collaborate in pushing the boundaries of what illumination can achieve. When you’re ready for a partner in innovation, reach out to my team here.