Putting this Powerful Lighting Solution to the Test

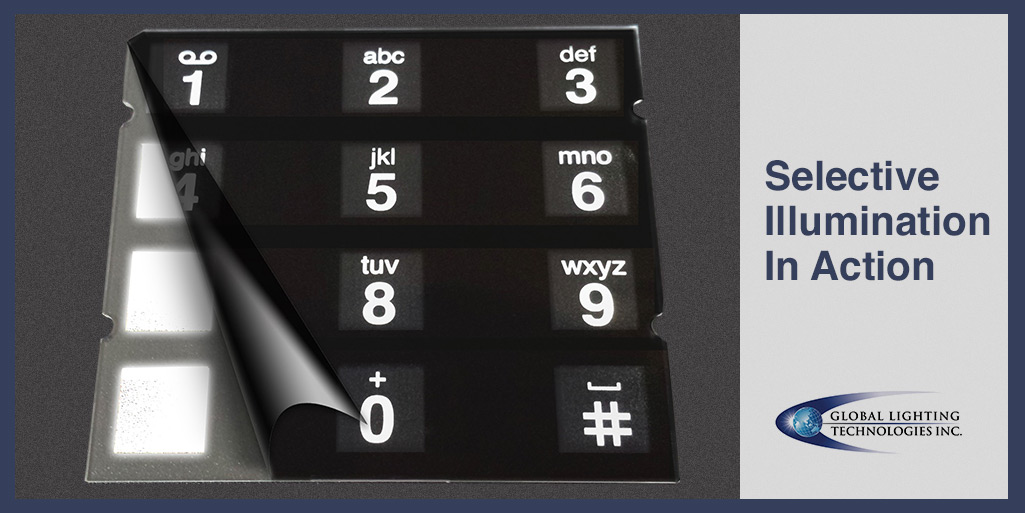

Selective illumination leverages special light-blocking materials to control specific areas of the backlight, reduce light bleed and improve user feedback. It’s especially effective for capacitive touch screen applications that require strong user feedback and image quality.

Here, we walk through how we implemented selective illumination technology for one of our valued customers.

The Challenge

Our first to-do for the project involved identifying the customer’s objectives and requirements, including targeted illumination zones, mechanical constraints, power maximums and target pricing. Essentially, the customer needed a drop-in illumination solution that required as few components as possible.

In the past, we cut slits into our light guides and inserted expensive foam materials to produce the desired light blocking effect. But, with cost objectives in mind, we determined that our time and budget-friendly overmolding technology could deliver better results.

The Solution

Before executing on the final product, we worked with our injection-molding division to develop light guide prototypes that tested our overmolding technology.

The overmolding process involved placing injection-molded light guides into a secondary injection-molding tool. Then, white or black plastic was injected between the light guides to create the light-blocking effect. It also delivered structural support to keep the pieces connected together.

The result: A single, secure and sturdy light guide that incorporated only two materials.

Once formed, GLT created individually-lit zones that allow our customer to control which areas of the end product light up for desired interactions or alerts. They also don’t need to worry about light bleed or other light-related interferences with the user experience.

A Seamless Process

Following the design and approval of the light guide structure, GLT engineers used in-house tooling and manufacturing technology to take the product from prototype to completion. With no outsourcing or third-parties needed, the entire development process was quick, efficient and cost-effective for our customer.

To learn more about this specialized lighting technology, read The Case for Selective Illumination.