What is Optical Film?

Optical film, or light management film, is a critical element necessary to craft custom light guides that help achieve customer goals. Often overlooked yet profoundly significant, optical films play a pivotal role because they protect the sensitive light guide while also spreading light across a surface. Here, we dive into the different types of optical films, their application and the role they play in the production process.

Optical Film vs Overlays: Unraveling the Distinction

Optical films and overlays sound like they could be similar, but in the realm of light guide production, they’re very different. Overlays are the top substrate of a final product provided by a customer while optical films are added by a light guide manufacturer during production.

Optical films (or light management films) are thin sheets of transparent material that are placed on top of the light guide for both protection and brightness enhancement and uniformity. Global Lighting Technologies and other light guide manufacturers apply different types of optical films to the light guide as part of the manufacturing process, then the final assembly is shipped to the customer. From there, the customer may add an overlay, depending on the application and industry their product is for.

An example is an auto manufacturer who wanted to create an illuminated gear shift. Our team designed and manufactured the custom light guide with an optical film on top, then the customer placed the light guide inside the gearshift module with a leather or plastic overlay on top.

It’s always helpful for our team to know what the final housing will be so we can make the proper recommendations for brightness and efficiency. However, if a customer cannot share that information or doesn’t know what the final housing will be, our team can also work to achieve a target brightness.

Now, let’s look at the different types of optical films and what they achieve.

Kinds of Optical Films: A Spectrum of Possibilities

The world of optical films offers a spectrum of possibilities. These films, each with a unique composition and purpose, play a nuanced role in shaping the quality of light emitted by the final product.

BEF: Brightness Enhancement Film

These films are super thin sheets of plastic measured in micrometers, usually between 65um-155um. Dual BEFs are slightly thicker and range from 125um-390um. BEFs are crafted from a PET base with a fine acrylic chemically spread on both sides. Their unique construction allows them to contribute significantly to the overall luminosity of the final light guide assembly.

Back Reflectors

The role of back reflectors is to capture light that may exit the bottom of the light guide and reflect it for optimal efficiency. They are often made of opaque white plastic and used as-is or a mirrored covering can be added for more reflection. Back reflectors are between 28um and 250um.

Diffusers

While BEFs and back reflectors enhance brightness, diffusers take on a different task. Made from a polyester base with a chemical coating, diffusers serve to scatter and soften light, contributing to uniform illumination. They range from 35um to 100um. Their strategic placement within the assembly process is key. They ensure that the final product achieves both optimal brightness and a visually pleasing and evenly distributed light output.

Each type of film plays a different role and, therefore, is added in different layers during production. Read on to learn more.

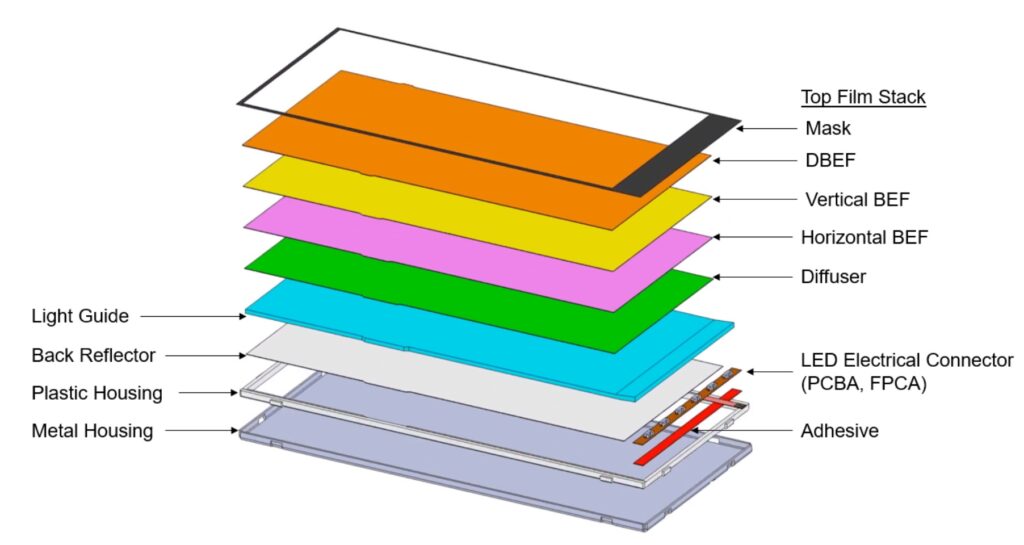

Optical Film Placement During Production

Precise component alignment is crucial for high-quality, long-lasting light guides. This applies to the placement of optical films as well. At Global Lighting Technologies, each component of a custom light guide is cut to size. Then, they’re layered one on top of the other for a pressure fit. From a light guide base to the top layer, here is how our components fit together:

- First layer: Housing or shell

- Back reflector

- Light guide containing our patented optical pattern

- Diffuser

- Final layers: BEFs

Small tabs on the side of the housing or shell keep all the components in place without the need for permanent bonding. This saves on material costs because components aren’t permanently adhered. Our designers and manufacturing teams have decades of experience that lead to the creation of precisely executed designs.

Visit our Videos page to learn more about our light guide production process.

Next, learn about the supplier vetting process that ensures we use high-quality., effective optical films.

Vetting Optical Film Suppliers: Precision from Source to Assembly

Ensuring the quality and stability of optical films begins with meticulous supplier vetting. Our global manufacturing facilities place great importance on sourcing from trusted vendors, some of which they’ve sourced from for years. Because optical film manufacturers are often also based in Asia, our manufacturing facility teams have the knowledge and experience to negotiate fair pricing.

Our US engineers often decide what kind of optical films to use, then our global teams source them. Our manufacturing facility teams may also provide insight into the best path forward based on their expertise.

The cost of optical films is mostly determined by thickness and functionality. For example, BEFs are typically the most expensive of the three films because of the technology required in manufacturing. Our team works with customers to tailor each aspect of your custom light guide. This ensures optical film recommendations are in your best interest.

Shedding Light on the Power of Optical Film

Light management films are powerhouse components that help us meet our customers’ goals and enhance their end-user experiences. For expert insight into the combination of optical films that can maximize your next illumination project, connect with our US engineers here.