How Tapered Light Guide Technology Supports Thin Applications

It can be a challenge to fit large LEDs into a small and thin application without sacrificing the sleekness or overall performance of the product. Enter: the tapered light guide.

For devices such as keyboards, handheld or wearable devices, and LCD displays, it’s hard to achieve bright, uniform illumination. Traditionally, you could increase the entire size of the light guide (which negatively impacts the application’s sleek aesthetic) or increase the number of LEDs needed (which decreases energy efficiency and causes a variety of visual defects).

Neither of these options are ideal for sleek applications.

Tapered Light Guide Design

Fortunately, we’ve solved this all-too-common problem with a dynamic light guide solution that doesn’t force you to sacrifice design, functionality or energy standards.

For many applications, we can utilize a standard light guide – a clear plastic plate – to manipulate or guide light to illuminate a surface evenly and efficiently.

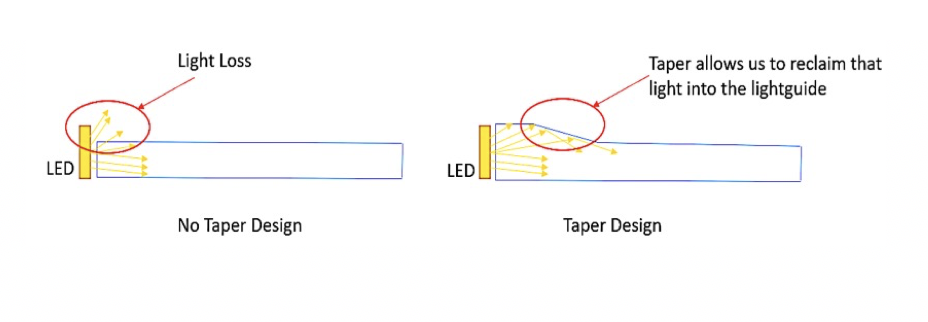

While standard light guides make sense in some areas, they aren’t optimal for small, thin applications. Why? This is because their consistent size and thickness aren’t ideal for using larger, more efficient LEDs to illuminate a display area. Instead, you must put multiple small LEDs into the application to hit a brightness target.

Knowing there was a need for a more efficient solution, our team developed a flexible alternative: The tapered light guide.

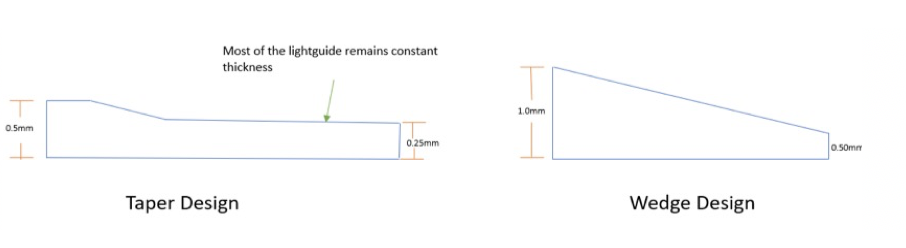

A tapered light guide has an increased thickness at one end but slims back down toward the other end. For example, the light guide thickness could start at 0.5 mm near one edge but decreases down to 0.25 throughout the rest of the part.

The benefit of the increased thickness at one end is that it allows you to use larger LEDs while maintaining the guide’s slim profile, uniformity, and visual appearance. This type of design is particularly conducive for lightweight consumer electronics that require a very thin backlight with high brightness and low power targets.

Although you’ve probably come across other lighting manufacturers that deliver tapered light guides, it’s important to note that our team has created parts that taper down to a thinness of 0.2 mm around the light emission area for the smallest of applications.

Small Difference, Big Impact

While the difference in size between a standard and tapered light guide is minimal, the result is extremely impactful. In the illustration below, you can see the tapered light guide claims all of the light emitted from the LED, leading to an improved aesthetic and increased energy efficiency. We all know how important good battery life is for our high-use portable devices.

Our proprietary manufacturing process enables us to create the thicker, tapered light guide design that can go all the way down to 0.2 mm at the other end (depending on the application) without adding secondary processes or increasing assembly space.

The tapered guide comes right off the manufacturing line as a finished product, just like our standard light guides, making it highly repeatable and extremely time and cost efficient, especially for high volume applications. Best of all, the design is completely customized and tailored to your size, brightness and power targets.

If you think you need a tapered light guide for your application, or aren’t sure which option makes sense for your project, we’re here to help. Our B2B light guide experts can work with you to identify your needs and develop a custom solution.

To speak with one of our representatives, please contact us today.