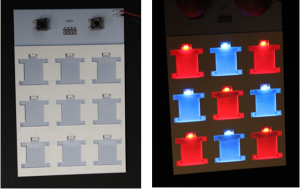

GLT continually seeks opportunities to innovate technology by utilizing our custom light guide solutions. With selective illumination, we leverage specialized light blocking materials to control specific areas of illumination within the backlight, reduce light bleed, and improve the user experience. Methods include light blocking material within voids in the light guide, over-molding of light guides with reflective light blocking material, or use of a double shot molding process. These products are especially effective for capacitive touch and overlay illumination. When used for these products, the light guide allows zones of illumination to operate independently and without light bleed.

Molded Solution

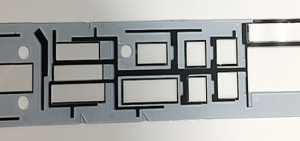

Zones of illumination are created within the light guide based on our customer needs. Through optical analysis and ray tracing software, LEDs are positioned within the assembly to allow for the most efficient illumination while limiting light bleed. Light blocking material is then added where necessary to further prevent light bleed across areas where discrete illumination is required. Finally, reflective and diffuse films can be assembled for a complete solution.

- Mechanical assembly of light blocking material

- Low level light bleed may occur

- Multiple components within final assembly

- Limitations for light blocking material based on die cutting processes

Over-molded Solution

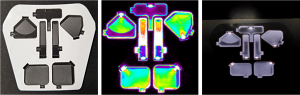

In order to improve on the light blocking ability and reduce component count, development was completed on an over-molded light guide manufacturing process. The illuminated light guide areas, as well as LED coupling regions are created within a custom injection mold tool. This optical light guide element is then placed within a second mold allowing for the over-molding of light blocking material.

- One piece final product

- Requires multiple injection mold tools

- Maximum light blocking performance

Double injection Solution

The latest development in selective illumination light guide technology utilizes a double injection molding process. Our engineers design the product to allow for the injection molding of the optical lightguide material within the illumination areas during initial molding, while a second material is then injected within the same mold to block light bleed between optical areas. This creates an injection molded product that meets the optical demands of the selective illumination market while reducing the number of components, reducing assembly time, and improving overall durability.

- One piece final product

- Complex injection mold tool

- Specialized injection press

- Maximum light blocking performance