Our Facility for Large Scale Extrusion Embossing

The Global Lighting Technologies plant in Tongluo, Taiwan is the heart of our large-scale extruded light guide production. This facility’s focus is producing light guides for TV and similar electronics manufacturers. Under the expertise of Plant Manager Preston Yeh and his team of 100 skilled professionals, Tongluo is a beacon of innovation and efficiency.

Brett Shriver, Vice President of Sales, interviewed Preston Yeh to dive deeper into the benefits of the extrusion embossing production process. Read on to learn how our Tongluo facility provides value to our customers around the world.

Extruded Light Guide Production

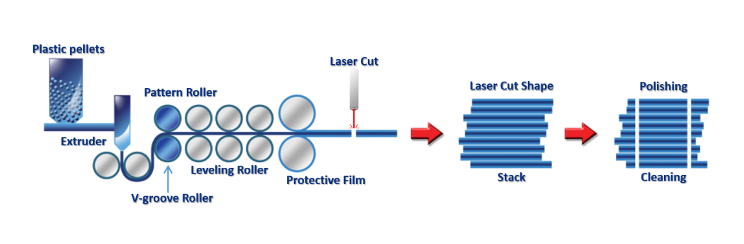

Extrusion embossing isn’t just a process – it’s a gateway to possibilities. This technique allows us to create large light guide panels with simple geometry at scale that cannot be created with injection molding due to size and thickness. Extrusion embossing works by feeding plastic pellets through a heated extruder; the pellets make their way through an extrusion die and then through a series of rollers that flatten the plastic and emboss the optical pattern on the surface.

After the extrusion process, the material is cut to length and width, and the edges are polished all using automation. Once the panels reach the end of the line, they are then stacked, packaged and ready for shipment.

Plant Manager Preston Yeh says, “Embossing allows for high accuracy replication of [our patented] optical patterns.” Better yet, extrusion embossing at Tongluo includes other benefits.

- Size and Thickness: Tongluo’s extrusion lines can handle parts up to 100 inch diagonally with thicknesses starting at a slender 0.8mm. This makes it the go-to process for efficiently crafting large and thin products from PMMA material.

- High Volume, Low Tooling Costs: The continuous extrusion process at Tongluo facilitates high-volume production with minimal tooling costs, making it an economically sound choice.

- Precision Through Replication: Extrusion embossing ensures the high accuracy replication of optical patterns for consistent and reliable performance.

Automation: The Efficient Pathway to Custom Cost Savings

At Tongluo, automation is the key to efficiency and cost savings when customer solutions require large-scale extrusion embossing. Most of the 100 employees at the facility are support staff for the equipment; they’re responsible for loading material into the extrusion lines, moving and shipping final product from the extrusion line, quality control inspection and management.

The marriage of automation and extrusion embossing isn’t just about streamlining processes; it’s a strategic move that translates into significant cost savings for customers. Here’s how:

- Reduced Labor Costs: With a highly automated facility, Tongluo minimizes its reliance on extensive manual labor. This not only streamlines operations but also reduces labor costs, contributing to overall cost-effectiveness.

- Minimized Downtime: Automated systems operate with efficiency and speed, significantly reducing production downtime. This translates into quicker turnaround times for customer orders and, consequently, faster time-to-market for their products.

- Optimized Material Usage: Automation allows for precise control over the extrusion process, minimizing material wastage. Our customers get the most out of their material investments, further contributing to cost savings.

By harnessing the power of automation in extruded light guide production, our Tongluo facility highlights our commitment to effective, fairly-priced solutions.

A Focus on Going Green

Aside from the benefits of extrusion embossing and automation covered above, Tongluo is also a “green” facility. Global Lighting Technologies selected this location due to the opening of Tongluo Science Park which focuses on green production plants. The location also conserves shipping and logistics resources because the Tongluo plant supports manufacturing customers in Taiwan and other nearby countries.

Similarly, our Zhongshan, China plant also specializes in large size extruded light guide production. However, it mainly supports customers who manufacture in China.

Extrusion Embossing at Tongluo, Taiwan

Large size, custom light guides produced at scale with cost savings built in may be a tall order at other light guide manufacturers; however, the Global Lighting Technologies team is ready to meet your needs efficiently at our Tongluo facility or another plant in our portfolio.

Whether you seek innovation, efficiency or a partnership that lights up your path, connect with our team here.