Table of Contents

- Our Process: The Proven Framework that Manufactures Success

- Stage 1: Pre-Discovery Qualification Sets the Foundation

- Stage 2: Discovery to Define Requirements and Set Goals

- Stage 3: Design Engineered for Results

- Stage 4: Prototype, Because Seeing is Believing

- Stage 5: Light Guide Manufacturing That’s Scalable, Certified, and Reliable

- Ready to Build a Partnership with Your Light Guide Manufacturer?

- Frequently Asked Questions

A guide for OEMs on our flexible, proven process that helps you go seamlessly from initial design and prototyping to global manufacturing.

Jonathan Tarnay

Project Sales Manager

Jon closely collaborates with OEMs throughout project lifecycles to understand their illumination needs and bring visionary ideas to life.

I hear from our clients that finding a light guide manufacturer who acts as a true partner can be a challenge. You need a collaborator who aligns with your internal workflows, provides expert guidance when you need it, and can scale production efficiently. A generalized manufacturer that offers lighting as a secondary service often delivers lackluster results, leaving you with a product that barely meets requirements. That’s not how we operate.

Our partnership model and proven process is different by design. It’s a customer-centric approach combining US-based project management and engineering with global manufacturing.

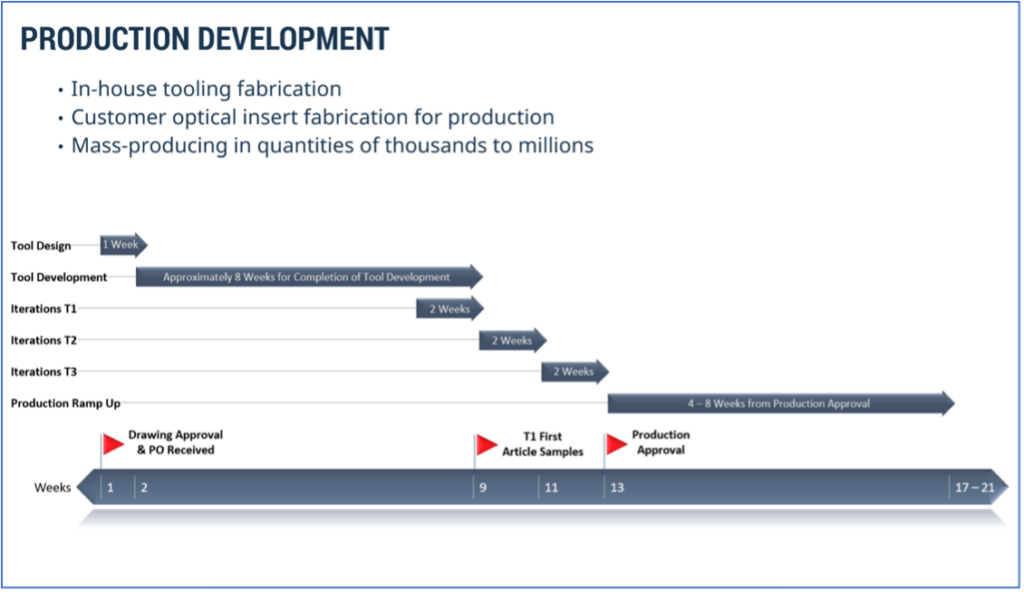

We provide clear communication and predictable outcomes from start to finish with dedicated support at every stage. This process is designed to minimize your risk, accelerate timelines, and ensure a smooth transition from a complex concept to a reliable, mass-produced product. We’re often asked how long it takes to go from the end of the prototype stage to market. See below for our project framework timeline.

Let’s step through our process together. We’ll cover key stages like Qualification, Discovery, Design, Prototype, and Manufacture.

Our Process: The Proven Framework that Manufactures Success

Unlike other light guide manufacturers, the OEMs who partner with us work with an engineer from initial concept through mass production. As Brett Shriver, now President of Global Lighting Technologies, points out, our engineers truly engage with customers.

Brett, now the President of Global Lighting Technologies, also touches on our distinct process framework:

- Pre-Discovery & Discovery: Share your requirements, then speak with an engineer to initiate concept design.

- Design: Collaborate with our engineers to create a light guide matching your fit, function, and performance requirements.

- Prototype: Complete concepting, receive a quote, begin the tooling process.

- Manufacture: Approve initial tooling and begin production at our global facilities.

Now that you have a general understanding of the process, we can dig into the details. Up first, is our pre-discovery qualification stage.

Consult our experts for your project.

Stage 1: Pre-Discovery Qualification Sets the Foundation

Every successful partnership begins with ensuring we’re the right fit for your project. Our process starts with a thorough qualification stage focused on one thing: manufacturing custom edge-lit light guide illumination. Reviewing your initial details is critical to aligning our capabilities with your vision and setting the foundation for a productive collaboration.

Your outreach connects you with our sales and engineering teams, who work together to assess the key details of your project. We review your end product, project schedule, projected production volumes, cost targets, and primary objectives.

This early assessment helps determine project feasibility and surfaces potential obstacles before they can impact your timeline. By working with a skilled team from the very start, we save you valuable time and ensure a smoother path forward.

Stage 2: Discovery to Define Requirements and Set Goals

Once we confirm the project is a strong fit, we move into the Discovery stage. This is a collaborative kickoff where you engage directly with a Global Lighting Technologies engineer to collect more necessary details.

We dive deep into your requirements, discussing assembly components, mechanical constraints, and illumination specifications. Our team asks proactive questions to clarify the vision for your product.

We cover topics like:

- Optical properties

- Power consumption

- Color requirements

- Environmental or testing standards that must be met

Even if you don’t have all the answers, we’ll recommend optimized solutions. The next stage is to design the light guide that brings your vision to life.

Stage 3: Design Engineered for Results

During the Design stage, your project is assigned to a Direct Responsible Engineer who becomes your consistent point of contact from design through production. This ensures seamless communication and a deep understanding of your project’s nuances.

If requirements change, your dedicated engineer collaborates with both our team and yours to assess feasibility and adapt the plan accordingly.

A critical part of this stage is digital validation. We use advanced software to create digital simulations of your product, allowing for early review and collaboration before we move to physical prototypes.

This step gives you a clear preview of the final performance and helps refine the design for optimal results. Seeing how the light will behave in a simulated environment provides confidence and alignment before committing to tooling.

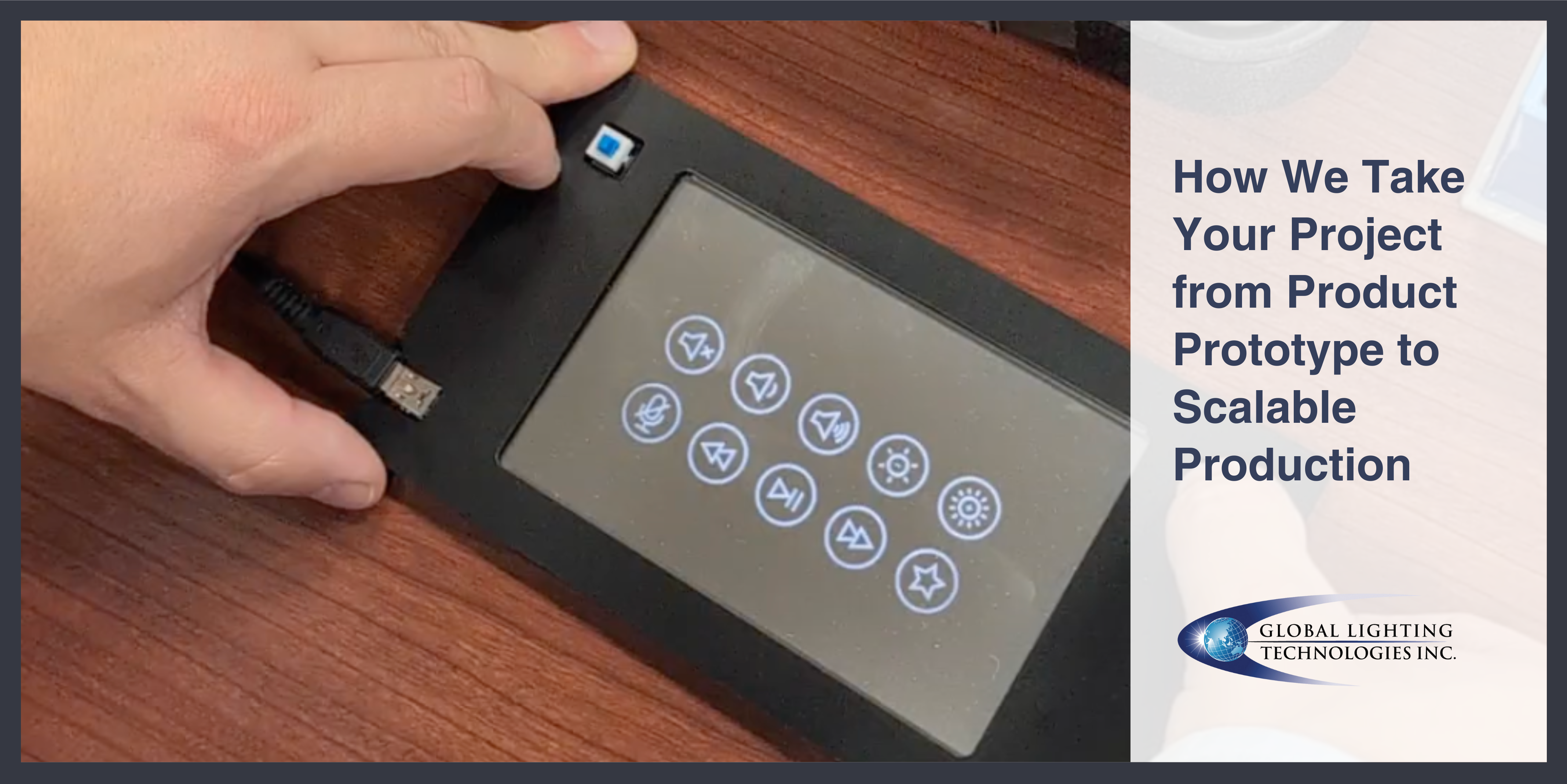

Stage 4: Prototype, Because Seeing is Believing

Working for a light guide manufacturer, I get particularly excited about the prototype stage. It’s when the design begins to come to life! We cover our proven prototype methodology in depth here, in our practical guide for project engineers.

A physical prototype helps validate performance, gain leadership approval, and allows your team to test the product in real-world scenarios before manufacturing begins. Unlike a light guide manufacturer who may outsource this critical step, our prototypes are built in-house by our own engineers.

You continue to work with the same dedicated engineer from the Design stage, ensuring all feedback is understood and integrated with precision. This integrated collaboration reinforces quality control and ensures the prototype accurately reflects your vision.

Once complete, the prototypes are shipped directly to you for your team to review, test, and validate, giving you tangible proof of the design’s effectiveness. After the prototype is approved, we move on to the final stage: manufacturing.

Stage 5: Light Guide Manufacturing That’s Scalable, Certified, and Reliable

For manufacturing, your design is sent to one of our five ISO- and IATF-certified manufacturing facilities for consistent, high-volume production.

We can produce quantities from thousands to millions of units using one of our primary manufacturing processes: injection molding, roll-to-roll embossing, or extrusion embossing.

Injection Molding

Injection molding is a manufacturing technique that injects molten material into a mold to create intricate and precise shapes. This process is crucial in forming the polymer-based components of light guides.

Roll-to-Roll (Thin Film) Embossing

Thin film embossing is a specialized manufacturing method we use to emboss precise optical patterns on light guide plates. This manufacturing method is ideal for applications that require high production volumes of light guides with simple geometries.

Extrusion Embossing

This technique allows us to create large light guide panels with simple geometry at scale that cannot be created with injection molding due to size and thickness.

Ready to Build a Partnership with Your Light Guide Manufacturer?

Our partnership model is designed to reduce your risk through early collaboration, accelerate timelines with rapid prototyping, and deliver scalable, high-quality production managed by a dedicated US team. The result is a process that builds confidence and delivers illumination solutions that meet both technical and business goals.

If you are ready to partner with a light guide manufacturer that integrates with your workflow and prioritizes your success, we invite you to start the conversation

Jonathan Tarnay

Project Sales Manager

Jon closely collaborates with OEMs throughout project lifecycles to understand their illumination needs and bring visionary ideas to life.

Light Guide Manufacturer FAQs

Who will be my main point of contact at Global Lighting Technologies?

You will have a dedicated, US-based Direct Responsible Engineer assigned to your project. They will be your consistent point of contact for all technical updates, information requests, and design changes, collaborating with you from the initial design to your product’s end of life.

Are there any upfront engineering or development costs?

No, Global Lighting Technologies does not charge for engineering time or have upfront development costs. You only pay for prototypes if they are required for your project. This approach allows your team to explore and validate concepts without a significant initial financial commitment, with tooling investments for production following prototype approval.

How long does it take to get a prototype?

The timeline for a prototype depends on the production method used. A typical laser-etched prototype can be completed within four to six weeks. If your prototype requires an injection-molded part, soft tooling extends the timeline to about four weeks, which is still faster than the six to eight weeks required for full production tooling.

What happens after I approve my prototype?

Once you approve the prototype, your project moves into the Manufacture stage. Your design is sent to one of our global facilities for consistent, high-volume production using injection molding, roll-to-roll embossing, or extruded embossing. While our sales team resumes project management for logistics, your Direct Responsible Engineer remains involved to provide technical

Can GLT help select or recommend LEDs for my project?

Yes. Our engineering team can recommend or source LEDs to meet your project’s specific brightness, color, and efficiency needs. This ensures that your prototype not only delivers the intended illumination but also provides a realistic preview of final product performance.

How does Global Lighting Technologies ensure quality is the same across all its global facilities?

We maintain consistent quality across our ISO- and IATF-certified facilities in Taiwan, China, and Vietnam through standardized processes, automation, and centralized US-based project management. Our teams use advanced quality control tools like confocal microscopes and CCD cameras to ensure every part meets the exact same optical performance and quality specifications, regardless of where it was manufactured.