How a Custom Light Guide Can Help Overcome Illumination Challenges for Medical Devices

The path to illuminate a medical device presents unique challenges; it requires a specific solution to specific applications. As a medical device manufacturer, you know that devices range in size and function, from small surgical retractors to blood sugar meters and displays on larger machines like MRIs. Despite these differences, the solution to more effectively illuminate medical devices is a custom medical device light guide.

After working with dozens of medical device manufacturers, we’ve seen the positive impact of highly effective custom light guides in medical environments. They’ve become as important to healthcare as clear overhead lighting, but can be more complex to execute well. Read on to explore the benefits of a custom medical device light guide, plus insights into illumination requirements for different medical devices.

Common Medical Device Illumination Requirements & Challenges

A medical device light guide can play a pivotal role in optimal optical performance in many types of medical equipment, from surgical tools to diagnostic devices. That said, they come with their own set of illumination requirements and challenges.

Common Medical Device Illumination Requirements

Similar to the proven process we follow for all projects, we ask clarifying questions to understand your medical device and illumination goals. In turn, customers often have questions for us! Here are the top questions from our medical device OEM customers:

- Have you worked in the medical industry before? We’ve supported dozens of medical device manufacturers.

- Can you guarantee supply for a certain number of years? We’ve been in business for over 20 years and are a publicly traded company. We’ll be here to support you on your project for as long as it’s in production! As with any manufacturer, some materials (like LEDs) can go EOL, but we are vigilantly review and replace these components with approved, qualified equivalents.

We welcome these questions at the project onset because it ensures our team and yours have all the information needed to make informed choices. A strong light guide manufacturing partner will provide you with all the key information you need to innovate a new device.

Medical Device Manufacturing and Engineering Challenges

One hurdle unique to medical settings is that equipment needs to be cleaned and sterilized. Think of surgical retractors used to hold body cavities open that must be sterilized after surgery, as mentioned above. Cleaning this type of medical device often requires harsh chemicals that can damage equipment. Two common solutions are a light guide that is

- integrated in the device, which protects it from damaging substances.

- a disposable portion of the assembly which is replaced after each use.

Medical device manufacturing also has its own challenges. For example, many medical devices have very limited production volumes because they’re complex and expensive. High-cost equipment such as MRI machines or specialized devices have long life expectancies and are sold infrequently. It’s important to work with a light guide manufacturer who takes a custom approach to your project so can achieve your production goals. A custom approach led by an experienced light guide manufacturer allows for significant design flexibility versus adapting an off-the-shelf component to meet your needs.

As you’ve likely encountered, time to market is also a manufacturing concern. If the product or device must go through clinical trials and FDA review/approval, the product development lifecycle could stretch to several years. Any snags in prototyping and testing can tack on additional time that you don’t have. A seasoned light guide manufacturer with a proven prototype process will help smooth the path to market. Explore how a robust prototype methodology can help you save time and resources.

A Custom Medical Device Light Guide Success Story

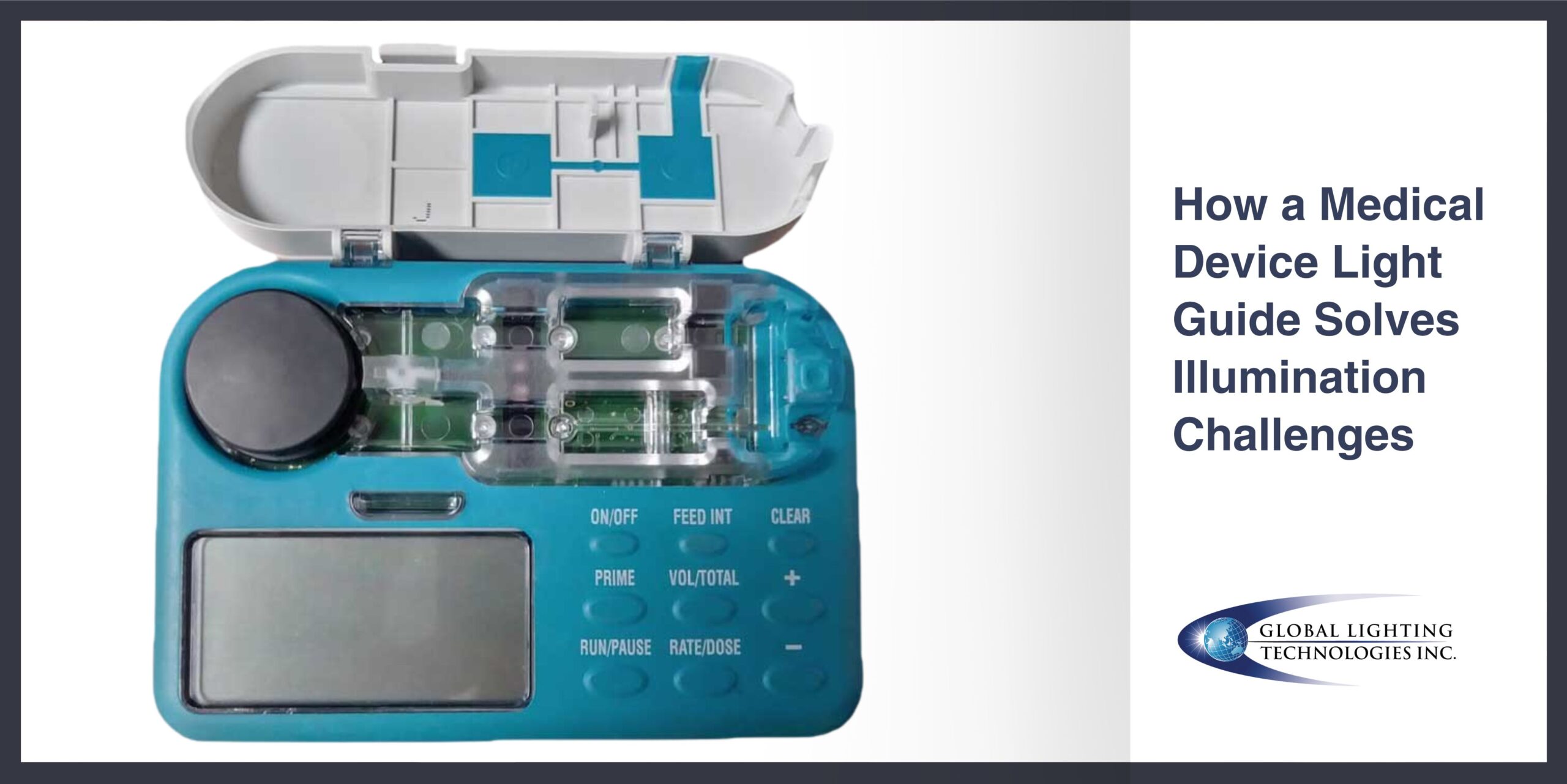

One customer approached our team to create a medical device light guide to illuminate a medical feeding pump LCD. Because the device is battery powered, we developed the illumination module so the resulting illumination was uniform and efficient. This allowed the device to maximize its battery power.

Another medical device manufacturer wanted to create a glucose meter that was as small as possible. They collaborated with us to integrate clips in our light guide assembly which would hold the LCD to the light guide as well as hold that assembly to their PCBA. Along with this, we integrated structure within the light guide to hold the elastomeric connection between the LCD and PCBA. Explore another medical device light guide customer success story in more detail here.

Optimal Optical Performance for Medical Devices

Your end users – whether they’re surgeons, doctors, nurses or consumers at home – deserve medical devices that provide the necessary illumination for their environments. Because medical device illumination needs range depending on the device and use case, we recommend custom light guides for optimal optical performance.

These are the most common applications that have required a custom light guide from our team, but we also welcome the challenge of new innovations. In all cases, high performance is crucial because illuminated displays provide key information to users. Uniform, consistent illumination can be critical to patient health and wellbeing, so medical device displays must function properly.

- Feeding and Infusion Pumps – Illumination is necessary for the LCD and keypads or user interfaces on the device. If the pump is battery operated, then high-efficiency light guides are needed to maximize power usage. Illumination uniformity is also important so users can read the display in all lighting conditions.

- Blood Sugar Meter – This small device can be handheld or worn on a patient’s wrist. The small screen or user interface needs illumination so it’s visible in all lighting conditions. Blood sugar meters are commonly produced in high volumes and are close to our production process for watches or consumer electronics device.

- Surgical Retractor – This device must provide even and high-level illumination of a bodily cavity without casting shadows. That’s often a challenge that an expert light guide manufacturer can help solve. Surgical retractors also need to withstand bodily fluids and sterilization, plus be free from materials that could harm the patient.

- Dental UV Curing Light – Dentists use this to cure adhesive or gel during dental procedures. It’s important that light is directed only onto the area which needs to be illuminated for an effective curing session. Plus, its best practice to limit light bleed, which can be harmful to anyone without protective eyewear.

We ensure optimal optical performance with custom optical patterns in our light guides. For every medical device light guide project, we develop optical patterns specifically for that application. Our engineers evaluate the many requirements based on the final device use and collaborate with your team throughout the entire process. Learn more about our approach to custom optical patterns here.

Rely on Our Expert Medical Device Light Guide Integration

The right light guide manufacturing partner provides key information and solutions to ensure your medical device functions as intended. Plus, they know leading questions to ask that get to the heart of your requirements and goals. Our team of experts has decades of medical device illumination experience and takes pride in delivering impactful solutions. Connect with us to share your medical device illumination needs.

Explore other common applications where light guides make an impact.